Pioneering green tech eyes space application, industry boost

Hong Kong scientist has dual vision to convert CO2 into diverse products

Industrial application

A State-owned Shanghai petrochemical plant agreed to trial Lau's system, spurred by the heated discussion about the introduction of carbon taxes. However, commercial viability will require scaling the tech 1,000-fold.

"Nobody adopts breakthroughs without profit pressure," Lau said. "Megawatt-scale is the threshold for real interest."

Lau is proposing to install his system in the third phase of Hong Kong's waste-to-energy facility.

The first phase, I.PARK1, currently under construction on reclaimed land off Shek Kwu Chau island, will be equipped with six incineration boilers and six flue gas treatment modules. It will process 3,000 tons of municipal waste daily once it is in use in 2025, exporting up to 480 million kWh of surplus electricity annually, enough for 100,000 homes.

Studies are underway for the second phase of the facility, located at Tuen Mun district's Tsang Tsui, which is planned to double the handling capacity of the first facility.

With phase II's tender period ending in October, Lau said design changes are unlikely once the facility is approved or built — making phase III his target for integration of his technology.

The three facilities support Hong Kong's goal to divert 11,000 tons of daily landfill waste, eventually ceasing the use of two of the city's three landfills before 2035.

Lau, who estimates half a ton of carbon dioxide will be emitted for every ton of municipal solid waste handled, is hoping for approval from the Hong Kong Special Administrative Region government to collect data for assessing the emissions from I.PARK1.

"CO2 isn't typically classified as a pollutant," Lau explained, "so the government doesn't maintain official records of its emissions."

Lau will use data on CO2 levels from burning different waste types to refine his system, calling it vital for the technology's development and future global use.

Eager for implementation

Waste-to-energy facilities with integrated CCUS technology like Lau's, offer synergy by providing concentrated sources of CO2. Power plant flue gas, for example, contains 20 to 30 percent carbon dioxide and presents cost-effective emission reduction opportunities.

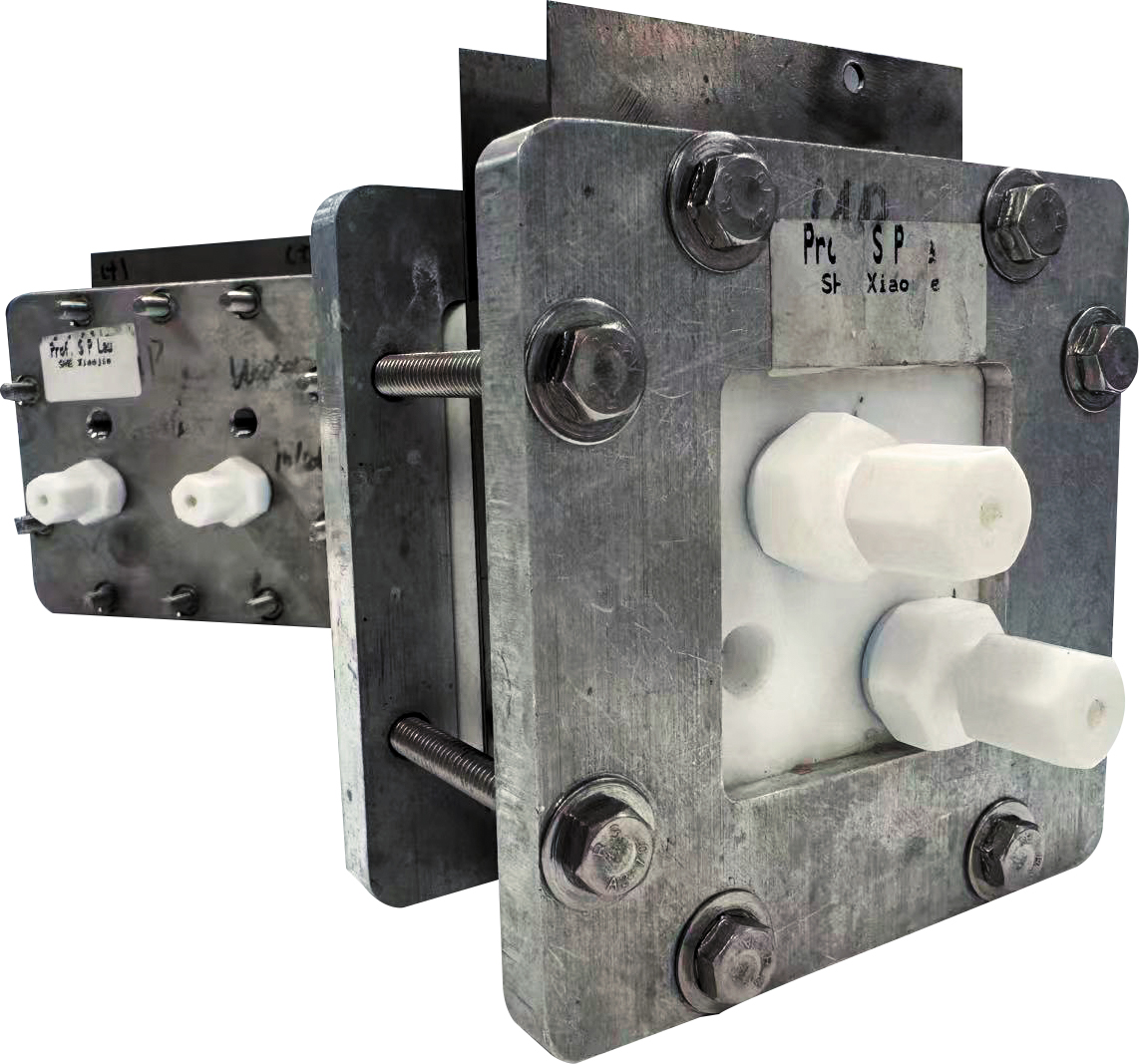

Lau's renewables-powered system currently processes 0.5 tons of CO2 annually. He is seeking funding support to build a system that is capable of handling 1000 tons of CO2 annually.

Despite the technology's potential, Lau has temporarily abandoned startup plans, citing exhausting investor searches and excessive resource demands. Instead, he's pursuing business partnerships for direct installation, particularly targeting mainland petrochemical firms rather than local power plants.

One of China's state-owned petrochemical companies has expressed interest in adopting Lau's technology to produce not just ethylene, but also methanol and ethanol from CO2 — all technically feasible applications.

"Ethylene, easily separated as gas, is operationally efficient and in high demand for plastic production," Lau said, describing a circular process where recycled plastic is incinerated.

While CCUS-produced ethylene costs twice as much as traditional production methods, Lau expects mainland industries that are facing pressure to reduce emissions to adopt it first, despite holding patents in the United States and Europe.

While industrial use requires scaling up, possible use in future Mars missions needs the opposite.

Lau's team is working on miniaturizing the device to just 90 grams for space missions.

Early tests aboard China's SJ-19 satellite in 2024 confirmed the catalyst works in space. "If successful, this could join Mars expeditions after 2030," Lau said.

- Village in Guangzhou announces subsidy for patients with mosquito-borne diseases

- Guangdong railways set passenger record during National Day holiday

- 'Inner Mongolia Day' opens at Expo 2025 Osaka

- China to hire 7,000 retired teachers to support rural schools

- Crested ibis soars again on the back of conservation efforts

- China launches emergency response after quake strikes SW China's Sichuan